You would expect that two weeks prior to the race, no more work is being done on decreasing the air resistance of our solar car, but you would be wrong. After a successful windtunnel-test in the German Dutch Wind Tunnels (DNW in Marknesse) past July, we started work on the design of an inner wheel cover to decrease Nuna6´s air resistance even further. In the following piece, we will explain how this works and why this inner wheel cover is so important.

During almost half a year we worked on the aerodynamic design of Nuna6. About 70% of the energy consumption of Nuna6 is due to the resistance exerted by the air resistance. Everything revolves around the force the air exerts on the car, in forms of both pressure- and frictionresistance. During our designphase we built 3 wind tunnel models and tested them in our Aerospace Engineering faculty’s wind tunnel at TU Delft. These models followed each other and each was a new step in a long optimization process, which ended in a car with the lowest air resistance of all Nunas.

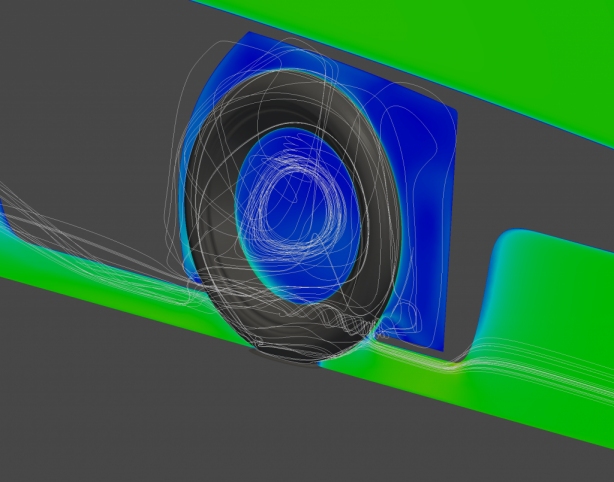

Unfortunately, we could only test our car in static conditions in the tunnel. This means that the wheels of Nuna6 were not able to turn and hence the effect this process brings along is neglected during the measurement. Due to the complexity of this problem it is very difficult to make a model that can exactly calculate the effects of a turning wheel. However, we know the effect of a turning wheel on the oncoming air is significant and there is a lot of profit to be made on this field. The oncoming air has an amount of kinetic energy and gets sucked into the car, where it will come to a hold and result in energy loss. This loss in impulse translates to a higher air resistance.

With this theory in mind we designed this inner wheel cover. This was a technical challenge because the degrees of freedom were limited due to the presence of the front wheel suspension. Also, it is of importance that in case of a flat tire or impact of rocks, the inner wheel spat does not damage the car, which could in turn bring the driver in danger. Different prototypes were made and used in an intensive testing process on rough roads and cattle grids to result in the final design. At the moment, Nuna6 has already driven thousands of kilometers on public Australian roads with these covers attached and results were very positive. We are eager to see how they perform in race conditions!